The ROSS sole flexure testing machine is mainly used to test the fatigue resistance of materials such as shoe soles under repeated bending. It is suitable for rubber products, shoe soles, PU materials, and other products. By simulating the repeated bending action of shoe soles during wear, it evaluates the changes in properties such as cracking and wear after material fatigue. Ross Flexural Strength Tester Shoe Sole Repeated Bending Life Tester Rubber And Leather Flexural Fatigue Testing Machine

The ROSS sole flexure testing machine is mainly used to test the fatigue resistance of materials such as shoe soles under repeated bending. It is suitable for rubber products, shoe soles, PU materials, and other products. By simulating the repeated bending action of shoe soles during wear, it evaluates the changes in properties such as cracking and wear after material fatigue. Ross Flexural Strength Tester Shoe Sole Repeated Bending Life Tester Rubber And Leather Flexural Fatigue Testing Machine  The microcomputer tear strength tester is a professional device used to measure the tear resistance of materials, with a wide range of applications. According to relevant standards and equipment design, this type of instrument is mainly suitable for testing the tear strength of materials such as paper, cardboard, film, textiles, and non-woven fabrics. Specifically, it can be used to determine the tear strength of various types of paper, and can also be used to test lower-strength cardboard, making it an ideal experimental device for industries and departments such as papermaking, packaging, scientific research, and product quality supervision and inspection. Besides paper and cardboard, it can also be applied to the tear resistance testing of plastic films (such as polyolefins, polyesters, etc.), composite films, polymer materials, waterproof rolls, woven materials, and rubber latex products. Some models of the tester can also be extended to test heavy-duty packaging bags, stretch wrap films, paper subway tickets, and other products. Microcomputer Paper Tear Tester Film Packaging Tester Material Tear Strength Tester Digital Fabric Tear Tester

The microcomputer tear strength tester is a professional device used to measure the tear resistance of materials, with a wide range of applications. According to relevant standards and equipment design, this type of instrument is mainly suitable for testing the tear strength of materials such as paper, cardboard, film, textiles, and non-woven fabrics. Specifically, it can be used to determine the tear strength of various types of paper, and can also be used to test lower-strength cardboard, making it an ideal experimental device for industries and departments such as papermaking, packaging, scientific research, and product quality supervision and inspection. Besides paper and cardboard, it can also be applied to the tear resistance testing of plastic films (such as polyolefins, polyesters, etc.), composite films, polymer materials, waterproof rolls, woven materials, and rubber latex products. Some models of the tester can also be extended to test heavy-duty packaging bags, stretch wrap films, paper subway tickets, and other products. Microcomputer Paper Tear Tester Film Packaging Tester Material Tear Strength Tester Digital Fabric Tear Tester  The fully automatic insertion and extraction force testing machine is mainly used to test the insertion and extraction force performance of connectors, and is suitable for fields such as electronics, automotive, aerospace, and new energy. It is used to test the insertion and extraction force and lifespan of connectors such as USB, HDMI, and SATA, ensuring the reliability of electronic device interfaces. Contact Friction Testing Machine Fully Automatic Insertion And Extraction Force Testing Machine Life Testing Equipment

The fully automatic insertion and extraction force testing machine is mainly used to test the insertion and extraction force performance of connectors, and is suitable for fields such as electronics, automotive, aerospace, and new energy. It is used to test the insertion and extraction force and lifespan of connectors such as USB, HDMI, and SATA, ensuring the reliability of electronic device interfaces. Contact Friction Testing Machine Fully Automatic Insertion And Extraction Force Testing Machine Life Testing Equipment  The lens torsion tester is a high-precision, highly flexible testing device used to evaluate the torque performance and torque life of camera lenses and related components. By simulating the rotational motion encountered in actual use and applying varying levels of torque, the tester accurately measures and records relevant data, providing strong support for product design and manufacturing. It is widely used for torque testing and torque life testing of products such as camera modules, mobile phones, LCD monitor mounts, and rotary switches, ensuring that products meet torque performance requirements during the design and manufacturing process. Lens Torque Tester Lens Impact Tester Telescope Torsional Yield Stiffness Test Machine Camera Lens Push-Pull Torsional Failure

The lens torsion tester is a high-precision, highly flexible testing device used to evaluate the torque performance and torque life of camera lenses and related components. By simulating the rotational motion encountered in actual use and applying varying levels of torque, the tester accurately measures and records relevant data, providing strong support for product design and manufacturing. It is widely used for torque testing and torque life testing of products such as camera modules, mobile phones, LCD monitor mounts, and rotary switches, ensuring that products meet torque performance requirements during the design and manufacturing process. Lens Torque Tester Lens Impact Tester Telescope Torsional Yield Stiffness Test Machine Camera Lens Push-Pull Torsional Failure  The Mechanical Impact Collision Table Is Mainly Used For Higher Impact Acceleration Tests On Specimens To Assess The Extent To Which The Specimens Can Withstand Impact Damage. It Is Often Used In Environmental Testing Of Electronic Components, Electronic Circuit Boards, Batteries, Etc. This Test Equipment Complies With The "Basic Environmental Test Specification For Electrical And Electronic Products Ea: Impact Test Method" And "Iec68-2-27, Test Ea: Impact" And "Mif -Std202F》Specification Requirements For Impact Testing. Hydraulic Mechanical Impact Testing Machine

The Mechanical Impact Collision Table Is Mainly Used For Higher Impact Acceleration Tests On Specimens To Assess The Extent To Which The Specimens Can Withstand Impact Damage. It Is Often Used In Environmental Testing Of Electronic Components, Electronic Circuit Boards, Batteries, Etc. This Test Equipment Complies With The "Basic Environmental Test Specification For Electrical And Electronic Products Ea: Impact Test Method" And "Iec68-2-27, Test Ea: Impact" And "Mif -Std202F》Specification Requirements For Impact Testing. Hydraulic Mechanical Impact Testing Machine  This machine is suitable for simulating the needling of various batteries in the process of transportation and storage. The test should be carried out at the ambient temperature of 20℃±5℃. The battery connected with the thermocouple (the contact of the thermocouple is fixed on the large surface of the battery) is placed in the ventilator, and a corrosionless steel needle with a diameter of 2-8mm is used to Pierce the central position of the largest surface of the battery at a speed of 10mm/s~40mm/s. Keep any time and observe the test results of the battery does not explode, do not fire is qualified. Battery Acupuncture And Extrusion Machine

This machine is suitable for simulating the needling of various batteries in the process of transportation and storage. The test should be carried out at the ambient temperature of 20℃±5℃. The battery connected with the thermocouple (the contact of the thermocouple is fixed on the large surface of the battery) is placed in the ventilator, and a corrosionless steel needle with a diameter of 2-8mm is used to Pierce the central position of the largest surface of the battery at a speed of 10mm/s~40mm/s. Keep any time and observe the test results of the battery does not explode, do not fire is qualified. Battery Acupuncture And Extrusion Machine  The acceleration impact testing machine is used to measure and determine the impact resistance of the product or package, and assess the functional reliability and structural integrity of the test product in the impact environment. The impact test of conventional half-sine wave, post-peak sawteeth, trapezoid wave and other waveforms can be performed to realize the impact and impact energy suffered by the product in the actual environment, so as to improve the system or optimize the packaging structure of the product. The impact test index is: the peak impact acceleration can reach 5000-50000m/s2, and the acceleration duration is 0.2-1ms. You can understand the impact resistance of your products and the use environment according to the impact test results. Acceleration Shock Testing Machine

The acceleration impact testing machine is used to measure and determine the impact resistance of the product or package, and assess the functional reliability and structural integrity of the test product in the impact environment. The impact test of conventional half-sine wave, post-peak sawteeth, trapezoid wave and other waveforms can be performed to realize the impact and impact energy suffered by the product in the actual environment, so as to improve the system or optimize the packaging structure of the product. The impact test index is: the peak impact acceleration can reach 5000-50000m/s2, and the acceleration duration is 0.2-1ms. You can understand the impact resistance of your products and the use environment according to the impact test results. Acceleration Shock Testing Machine  The contact angle meter is used to measure the wettability of liquids on solids. It calculates and determines indicators such as the liquid's adhesion to the solid, surface tension, and surface energy of the solid by measuring the contact angle. This instrument is widely used in petroleum, chemical, pharmaceutical, papermaking, and dye industries for scientific research and educational purposes. The machine uses imported components and employs microcontroller technology to transfer captured images to a computer for storage, analysis, and printing. It is fast, provides accurate data, and is easy to operate. Manual Contact Angle Measuring Instrument

The contact angle meter is used to measure the wettability of liquids on solids. It calculates and determines indicators such as the liquid's adhesion to the solid, surface tension, and surface energy of the solid by measuring the contact angle. This instrument is widely used in petroleum, chemical, pharmaceutical, papermaking, and dye industries for scientific research and educational purposes. The machine uses imported components and employs microcontroller technology to transfer captured images to a computer for storage, analysis, and printing. It is fast, provides accurate data, and is easy to operate. Manual Contact Angle Measuring Instrument  The contact angle meter can measure the water droplet angle and contact angle of hundreds of materials, with applications including: fibers, displays, polarizers, camera modules, LEDs, thin films, wafers, etc., as well as materials testing and research in universities and research institutes. Fully Automated Contact Angle Meter for Wafers

The contact angle meter can measure the water droplet angle and contact angle of hundreds of materials, with applications including: fibers, displays, polarizers, camera modules, LEDs, thin films, wafers, etc., as well as materials testing and research in universities and research institutes. Fully Automated Contact Angle Meter for Wafers  The contact angle meter can measure the water droplet angle and contact angle of hundreds of materials, with applications including: fibers, displays, polarizers, camera modules, LEDs, thin films, wafers, etc., as well as materials testing and research in universities and research institutes. Inclined Automatic Contact Angle Measuring Instrument

The contact angle meter can measure the water droplet angle and contact angle of hundreds of materials, with applications including: fibers, displays, polarizers, camera modules, LEDs, thin films, wafers, etc., as well as materials testing and research in universities and research institutes. Inclined Automatic Contact Angle Measuring Instrument  The contact angle meter can measure the water droplet angle and contact angle of hundreds of materials, with applications including: fibers, displays, polarizers, camera modules, LEDs, thin films, wafers, etc., as well as materials testing and research in universities and research institutes. Automatic Contact Angle Meter

The contact angle meter can measure the water droplet angle and contact angle of hundreds of materials, with applications including: fibers, displays, polarizers, camera modules, LEDs, thin films, wafers, etc., as well as materials testing and research in universities and research institutes. Automatic Contact Angle Meter  This shock test bench can be used to perform shock tests on products, primarily for small specimens subjected to high shock acceleration. This test bench assesses the specimen's ability to withstand shock damage. It is commonly used for environmental testing of electronic components and circuit boards. This test equipment complies with the shock testing requirements of the "Basic Environmental Testing Specification for Electrical and Electronic Products, Test Ea: Shock Test Method," "IEC68-2-27, Test Ea: Shock," and "MIF-STD202F." Pneumatic Mechanical Shock Testing Machine High Acceleration Impact Collision Table Simulated Gravity Drop Impact Table

This shock test bench can be used to perform shock tests on products, primarily for small specimens subjected to high shock acceleration. This test bench assesses the specimen's ability to withstand shock damage. It is commonly used for environmental testing of electronic components and circuit boards. This test equipment complies with the shock testing requirements of the "Basic Environmental Testing Specification for Electrical and Electronic Products, Test Ea: Shock Test Method," "IEC68-2-27, Test Ea: Shock," and "MIF-STD202F." Pneumatic Mechanical Shock Testing Machine High Acceleration Impact Collision Table Simulated Gravity Drop Impact Table  The simulated three-level road bump tester is suitable for accelerated road transport simulation testing of truck-transported products to determine whether the product can withstand the expected transport vibration environment. Accelerated road transport simulation testing involves increasing the test value of simulated transport vibration on a simulation platform to shorten the transport simulation test time and conduct tests consistent with the statistical characteristics of fatigue cumulative damage in automobile transport environments. Simulated Level 3 Road Bump Tester Truck Highway Transport Acceleration Simulation Test Bench Carton Packaging Vibration Tester

The simulated three-level road bump tester is suitable for accelerated road transport simulation testing of truck-transported products to determine whether the product can withstand the expected transport vibration environment. Accelerated road transport simulation testing involves increasing the test value of simulated transport vibration on a simulation platform to shorten the transport simulation test time and conduct tests consistent with the statistical characteristics of fatigue cumulative damage in automobile transport environments. Simulated Level 3 Road Bump Tester Truck Highway Transport Acceleration Simulation Test Bench Carton Packaging Vibration Tester  Spring fatigue testing machine, spring durability testing machine, also known as microcomputer-controlled spring performance comprehensive test bench, is mainly used for fatigue life testing of various shock absorbers, shock absorbers, springs, etc. The whole machine has a reasonable structure, simple and reliable, accurate and convenient test space adjustment and test stroke adjustment; convenient and reliable specimen clamping; stable operation of the whole machine, easy maintenance and other characteristics. Five-station Spring Fatigue Testing Machine

Spring fatigue testing machine, spring durability testing machine, also known as microcomputer-controlled spring performance comprehensive test bench, is mainly used for fatigue life testing of various shock absorbers, shock absorbers, springs, etc. The whole machine has a reasonable structure, simple and reliable, accurate and convenient test space adjustment and test stroke adjustment; convenient and reliable specimen clamping; stable operation of the whole machine, easy maintenance and other characteristics. Five-station Spring Fatigue Testing Machine  This test equipment is mainly used for pressure testing of valves, containers, pipe fittings and other products. As the main equipment for detecting pressure, this test bench plays an important role in ensuring its quality and improving its reliability. The test water pressure, time, etc. can be controlled. Abnormal situations can be automatically handled, and the test report can be printed after the test is completed.

This test equipment is mainly used for pressure testing of valves, containers, pipe fittings and other products. As the main equipment for detecting pressure, this test bench plays an important role in ensuring its quality and improving its reliability. The test water pressure, time, etc. can be controlled. Abnormal situations can be automatically handled, and the test report can be printed after the test is completed.

The theme of this conference is "Core Ties, New Future", focusing on new markets, products, and technologies in the industry. Three main forums will be held: Summit Forum, High Quality Development Entrepreneurs Summit, and Innovation and Application Summit; Parallel forums such as the Yangtze River

Thank you for your strong support and love for our company, which has allowed us to move forward and develop steadily. In order to meet the market demand, the company is now expanding the production scale. From November 15, 2020, the production plant has been relocated to: No. 5, Mulun Industrial 2n

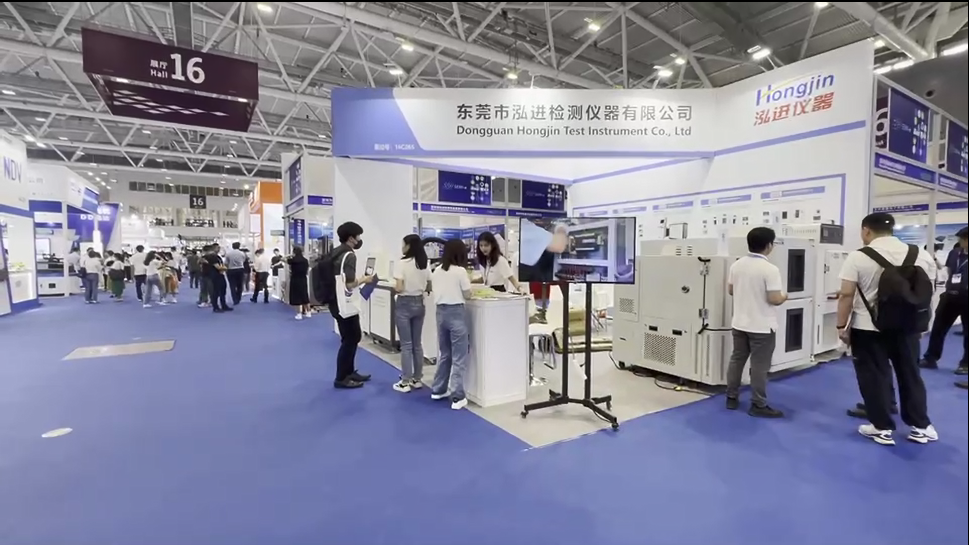

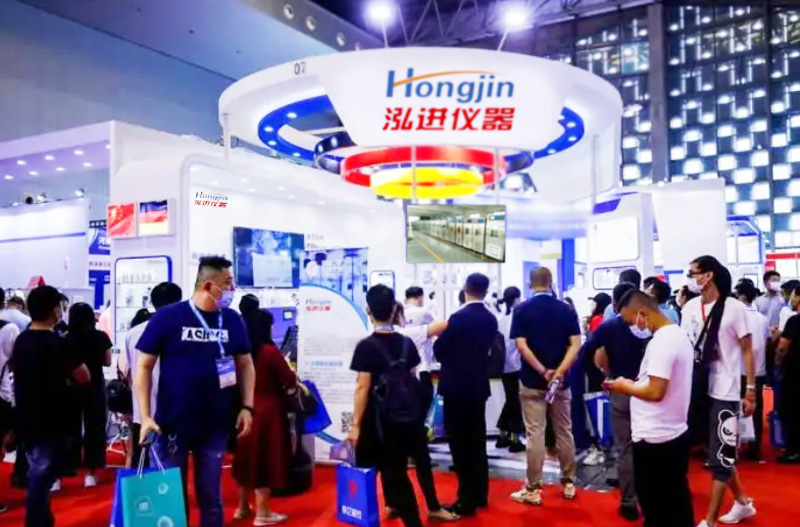

Hongjin Company participated in Shenzhen Semiconductor Exhibition Hongjin company participated in the semiconductor exhibition held in Shenzhen. The main products displayed are: thermal shock test chamber, HAST high pressure accelerated aging test chamber, PCT high pressure accelerated aging test

Today, old customers from Iran visited our company, visited 8 production workshops of our company, visited the exhibition hall,As well as the office, they complimented our precision ovens and decided on the spot to order 2 double door precision ovens. Thank you Iranian customers for their support to