| Availability: | |

|---|---|

| Quantity: | |

hongjin

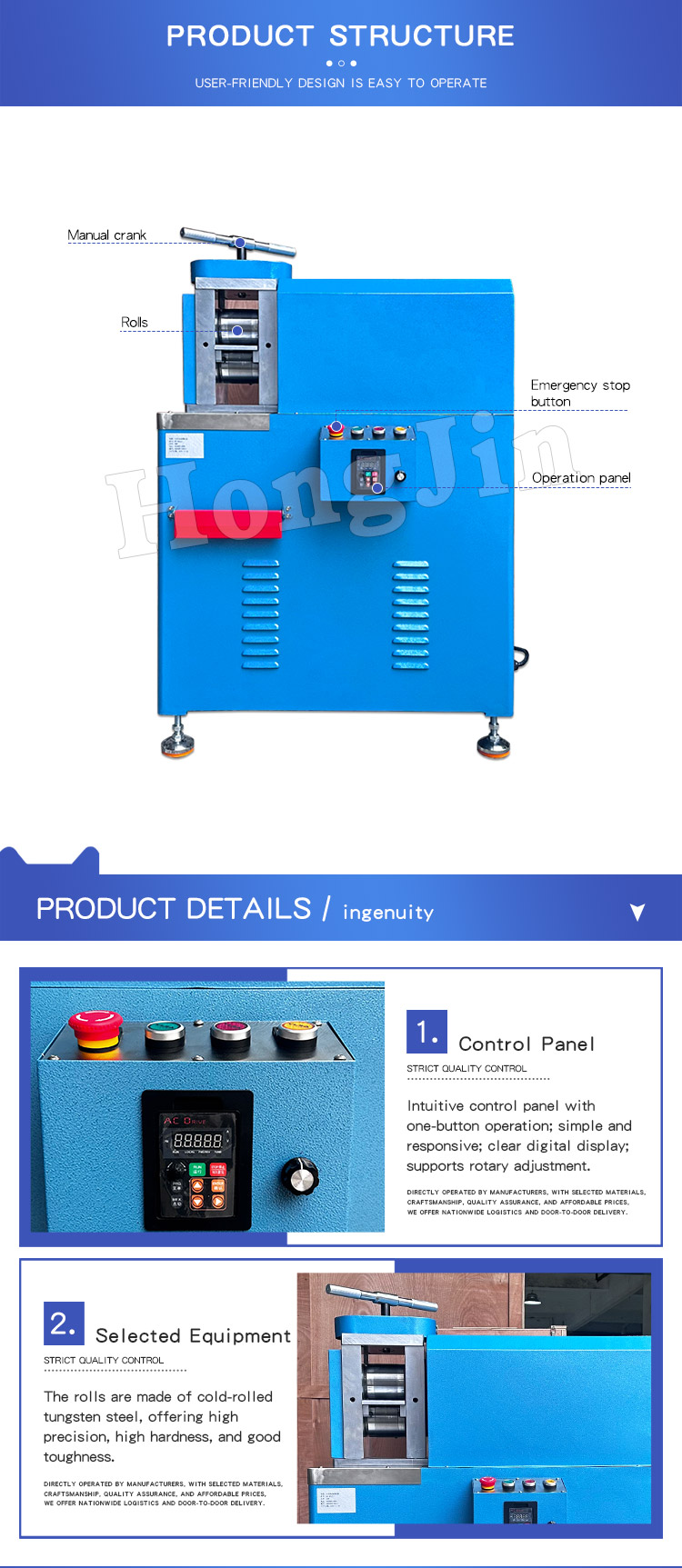

Product Introduction:

The electric rolling mill is a sheet or coil rolling equipment. Driven by a motor, the rollers perform the rolling process. It is suitable for rolling gold, silver, and copper sheets in the precious metals and hardware industries. The rolling thickness and speed are adjustable, providing good rolling uniformity and high precision. Operation is simple and convenient. For some soft materials, the thinnest size can be achieved with reciprocating rolling to 0.06mm, with a product precision of 0.01-0.02mm. Roll balance can be adjusted independently via a rocker arm. It features forward and reverse rotation, and the lower pressure plate has a graduated scale.

Product Features:

1. Integral gantry frame, CNC precision machining, ensuring high stability;

2. Rolls are made of cold-rolled tungsten steel, heat-treated and then surface-ground, resulting in high precision, high hardness, and good toughness;

3. Roll surface undergoes heat treatment through two processes;

4. Adjustable roll gap adjustment device;

5. Two-roll design, compact structure, suitable for various metal sheeting, convenient operation and maintenance;

6. Can roll materials: gold, silver, copper, platinum, palladium, aluminum, alloys, etc.;

7. Automatic oil supply system.

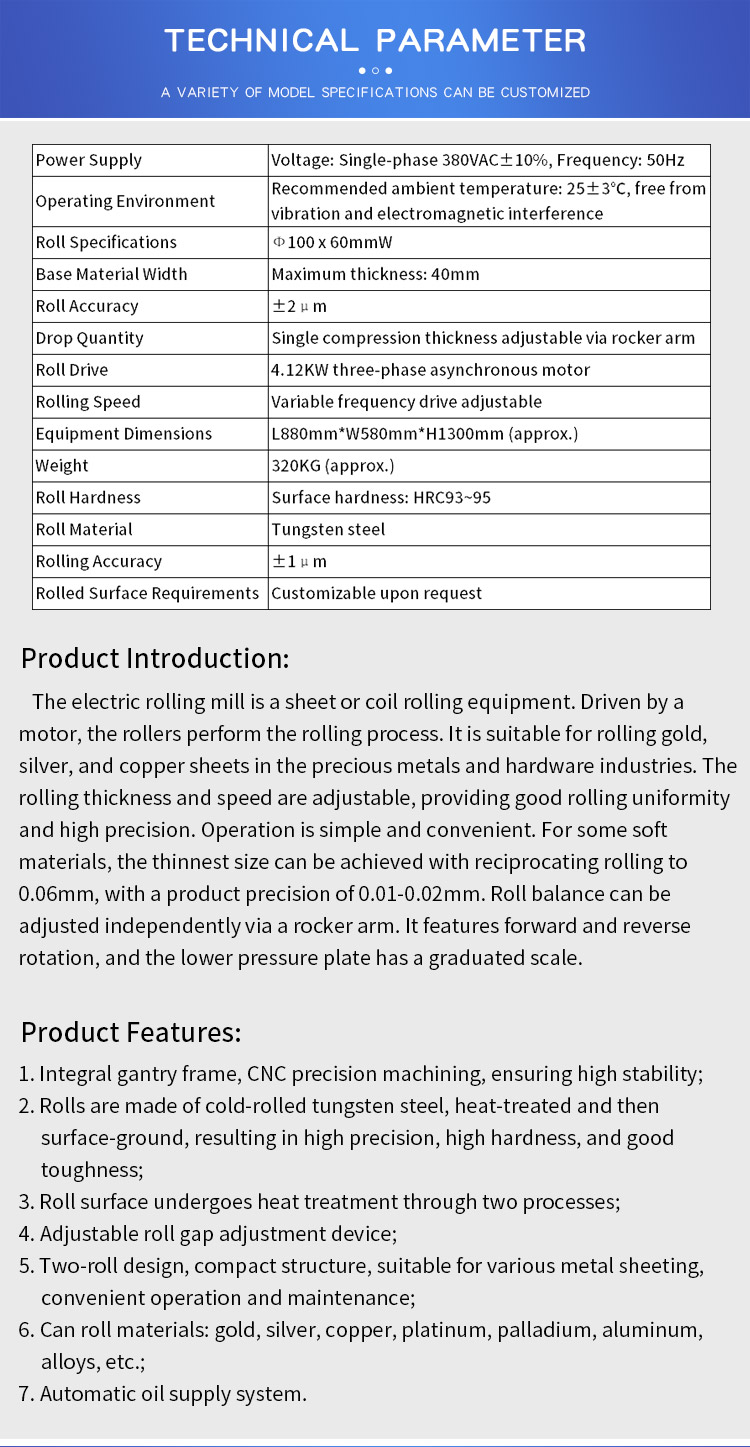

| Power Supply | Voltage: Single-phase 380VAC±10%, Frequency: 50Hz |

| Operating Environment | Recommended ambient temperature: 25±3℃, free from vibration and electromagnetic interference |

| Roll Specifications | Ф100 x 60mmW |

| Base Material Width | Maximum thickness: 40mm |

| Roll Accuracy | ±2μm |

| Drop Quantity | Single compression thickness adjustable via rocker arm |

| Roll Drive | 4.12KW three-phase asynchronous motor |

| Rolling Speed | Variable frequency drive adjustable |

| Equipment Dimensions | L880mm*W580mm*H1300mm (approx.) |

| Weight | 320KG (approx.) |

| Roll Hardness | Surface hardness: HRC93~95 |

| Roll Material | Tungsten steel |

| Rolling Accuracy | ±1μm |

| Rolled Surface Requirements | Customizable upon request |

Product Introduction:

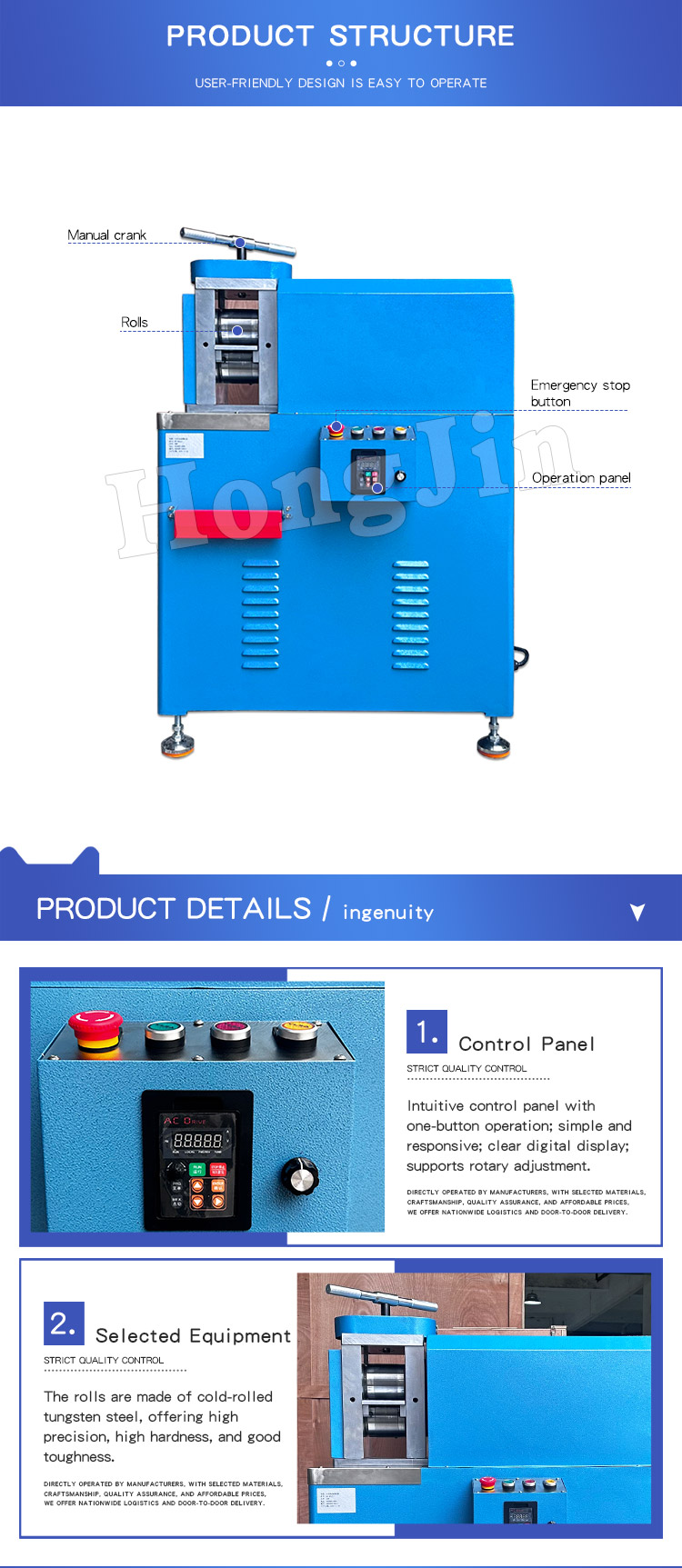

The electric rolling mill is a sheet or coil rolling equipment. Driven by a motor, the rollers perform the rolling process. It is suitable for rolling gold, silver, and copper sheets in the precious metals and hardware industries. The rolling thickness and speed are adjustable, providing good rolling uniformity and high precision. Operation is simple and convenient. For some soft materials, the thinnest size can be achieved with reciprocating rolling to 0.06mm, with a product precision of 0.01-0.02mm. Roll balance can be adjusted independently via a rocker arm. It features forward and reverse rotation, and the lower pressure plate has a graduated scale.

Product Features:

1. Integral gantry frame, CNC precision machining, ensuring high stability;

2. Rolls are made of cold-rolled tungsten steel, heat-treated and then surface-ground, resulting in high precision, high hardness, and good toughness;

3. Roll surface undergoes heat treatment through two processes;

4. Adjustable roll gap adjustment device;

5. Two-roll design, compact structure, suitable for various metal sheeting, convenient operation and maintenance;

6. Can roll materials: gold, silver, copper, platinum, palladium, aluminum, alloys, etc.;

7. Automatic oil supply system.

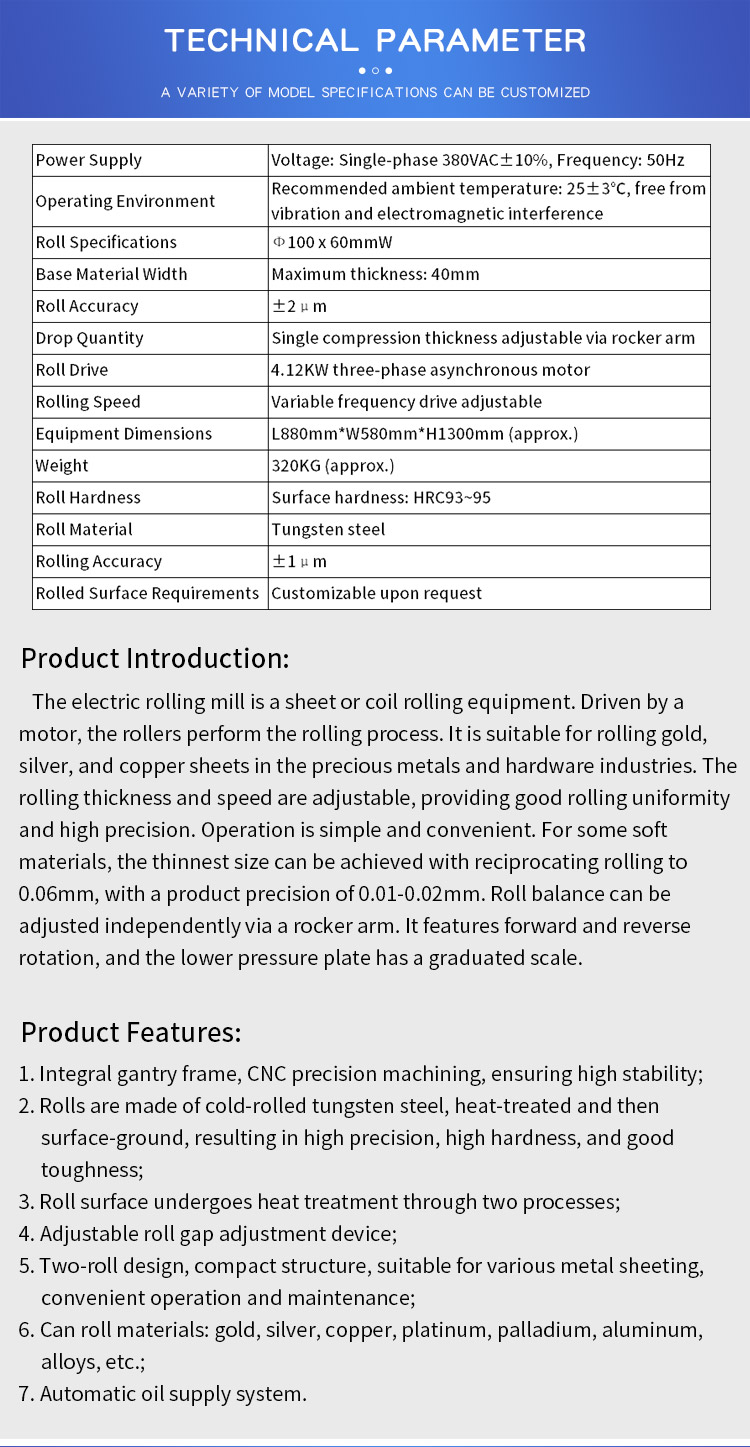

| Power Supply | Voltage: Single-phase 380VAC±10%, Frequency: 50Hz |

| Operating Environment | Recommended ambient temperature: 25±3℃, free from vibration and electromagnetic interference |

| Roll Specifications | Ф100 x 60mmW |

| Base Material Width | Maximum thickness: 40mm |

| Roll Accuracy | ±2μm |

| Drop Quantity | Single compression thickness adjustable via rocker arm |

| Roll Drive | 4.12KW three-phase asynchronous motor |

| Rolling Speed | Variable frequency drive adjustable |

| Equipment Dimensions | L880mm*W580mm*H1300mm (approx.) |

| Weight | 320KG (approx.) |

| Roll Hardness | Surface hardness: HRC93~95 |

| Roll Material | Tungsten steel |

| Rolling Accuracy | ±1μm |

| Rolled Surface Requirements | Customizable upon request |