| Availability: | |

|---|---|

| Quantity: | |

hongjin

Drying Oven Classification:

1. Based on performance:

Programmable drying ovens, precision drying ovens, nitrogen-filled drying ovens, vacuum drying ovens, explosion-proof drying ovens, electric heating forced-air drying ovens, hot air circulating drying ovens, etc. Widely applicable to components requiring drying and heating in various industries.

2. Based on industry:

Drying ovens for the electronics industry, electrical equipment industry, electroplating industry, printing industry, eyewear industry, synthetic fiber industry, wood industry, friction material industry, etc.

3. Based on shape:

Horizontal drying ovens and vertical drying ovens.

4. Based on rated temperature:

a. Low-temperature drying ovens: Below 100℃, generally used for aging electrical products, slow drying of ordinary materials, and drying of some food raw materials and plastics.

b. Normal-temperature drying ovens: 100-250℃, this is the most common operating temperature, used for drying most materials, curing coatings, heating, and heat preservation. c. High-Temperature Drying Oven: 250-400℃, used for high-temperature drying of special materials, heated installation of workpieces, high-temperature material testing, and reaction treatment of chemical raw materials.

d. Ultra-High Temperature Drying Oven: 400-600℃, with even higher operating temperatures, used for high-temperature drying of special materials, heat treatment of workpieces, and high-temperature material testing.

(We manufacture and sell all of the above drying ovens, and can customize them according to technical requirements.)

Product Features:

1. Optional Models:

a. Standard Partition Model: High load-bearing capacity, high flexibility, adjustable layering, suitable for large workpieces;

b. Built-in Turntable Model: 360° dynamic and uniform heating, shortens baking cycle, suitable for irregular workpieces;

c. Single-Layer Trolley Model: No layer obstruction, strong heating, large heating area, more energy-efficient, reduces manual handling intensity, suitable for oversized parts;

d. Multi-Layer Trolley Model: Integrated processing, high capacity, maximized production output, significantly shortens batch processing time, suitable for batch production of standardized workpieces.

2. Large-capacity, thickened chassis with a reinforced base frame;

3. Stainless steel inner liner, customizable to 304/316;

4. PID temperature controller with intelligent temperature control core;

5. High-power, silent fan for energy saving, reduced consumption, and extended service life;

6. Two-sided finned heating elements to reduce heat loss and enhance efficiency;

7. Upgraded, thickened insulation to reduce noise and improve high-temperature resistance;

8. Equipped with a trolley (load capacity can be selected according to customer needs).

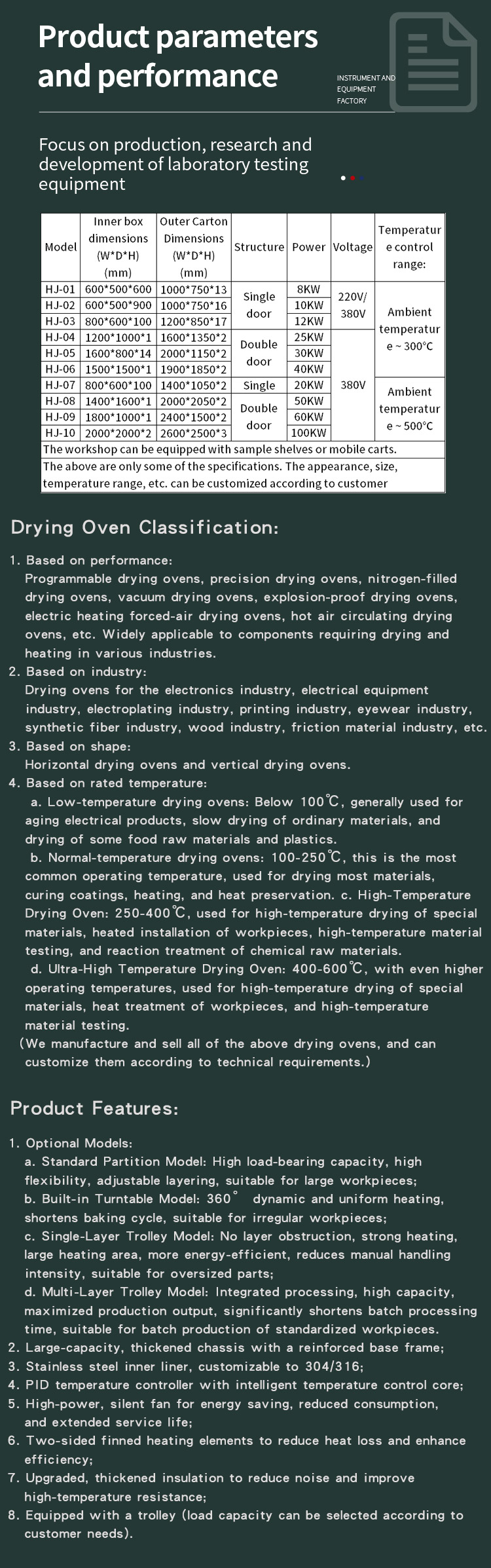

| Model | Inner box dimensions (W*D*H) (mm) | Outer Carton Dimensions (W*D*H) (mm) | Structure | Power | Voltage | Temperature control range: |

| HJ-01 | 600*500*600 | 1000*750*1300 | Single door | 8KW | 220V/ 380V | Ambient temperature ~ 300℃ |

| HJ-02 | 600*500*900 | 1000*750*1600 | 10KW | |||

| HJ-03 | 800*600*1000 | 1200*850*1700 | 12KW | |||

| HJ-04 | 1200*1000*1500 | 1600*1350*2300 | Double door | 25KW | 380V | |

| HJ-05 | 1600*800*1400 | 2000*1150*2100 | 30KW | |||

| HJ-06 | 1500*1500*1500 | 1900*1850*2200 | 40KW | |||

| HJ-07 | 800*600*1000 | 1400*1050*2100 | Single door | 20KW | Ambient temperature ~ 500℃ | |

| HJ-08 | 1400*1600*1400 | 2000*2050*2500 | Double door | 50KW | ||

| HJ-09 | 1800*1000*1500 | 2400*1500*2600 | 60KW | |||

| HJ-10 | 2000*2000*2000 | 2600*2500*3000 | 100KW | |||

| The workshop can be equipped with sample shelves or mobile carts. | ||||||

| The above are only some of the specifications. The appearance, size, temperature range, etc. can be customized according to customer requirements. | ||||||

Drying Oven Classification:

1. Based on performance:

Programmable drying ovens, precision drying ovens, nitrogen-filled drying ovens, vacuum drying ovens, explosion-proof drying ovens, electric heating forced-air drying ovens, hot air circulating drying ovens, etc. Widely applicable to components requiring drying and heating in various industries.

2. Based on industry:

Drying ovens for the electronics industry, electrical equipment industry, electroplating industry, printing industry, eyewear industry, synthetic fiber industry, wood industry, friction material industry, etc.

3. Based on shape:

Horizontal drying ovens and vertical drying ovens.

4. Based on rated temperature:

a. Low-temperature drying ovens: Below 100℃, generally used for aging electrical products, slow drying of ordinary materials, and drying of some food raw materials and plastics.

b. Normal-temperature drying ovens: 100-250℃, this is the most common operating temperature, used for drying most materials, curing coatings, heating, and heat preservation. c. High-Temperature Drying Oven: 250-400℃, used for high-temperature drying of special materials, heated installation of workpieces, high-temperature material testing, and reaction treatment of chemical raw materials.

d. Ultra-High Temperature Drying Oven: 400-600℃, with even higher operating temperatures, used for high-temperature drying of special materials, heat treatment of workpieces, and high-temperature material testing.

(We manufacture and sell all of the above drying ovens, and can customize them according to technical requirements.)

Product Features:

1. Optional Models:

a. Standard Partition Model: High load-bearing capacity, high flexibility, adjustable layering, suitable for large workpieces;

b. Built-in Turntable Model: 360° dynamic and uniform heating, shortens baking cycle, suitable for irregular workpieces;

c. Single-Layer Trolley Model: No layer obstruction, strong heating, large heating area, more energy-efficient, reduces manual handling intensity, suitable for oversized parts;

d. Multi-Layer Trolley Model: Integrated processing, high capacity, maximized production output, significantly shortens batch processing time, suitable for batch production of standardized workpieces.

2. Large-capacity, thickened chassis with a reinforced base frame;

3. Stainless steel inner liner, customizable to 304/316;

4. PID temperature controller with intelligent temperature control core;

5. High-power, silent fan for energy saving, reduced consumption, and extended service life;

6. Two-sided finned heating elements to reduce heat loss and enhance efficiency;

7. Upgraded, thickened insulation to reduce noise and improve high-temperature resistance;

8. Equipped with a trolley (load capacity can be selected according to customer needs).

| Model | Inner box dimensions (W*D*H) (mm) | Outer Carton Dimensions (W*D*H) (mm) | Structure | Power | Voltage | Temperature control range: |

| HJ-01 | 600*500*600 | 1000*750*1300 | Single door | 8KW | 220V/ 380V | Ambient temperature ~ 300℃ |

| HJ-02 | 600*500*900 | 1000*750*1600 | 10KW | |||

| HJ-03 | 800*600*1000 | 1200*850*1700 | 12KW | |||

| HJ-04 | 1200*1000*1500 | 1600*1350*2300 | Double door | 25KW | 380V | |

| HJ-05 | 1600*800*1400 | 2000*1150*2100 | 30KW | |||

| HJ-06 | 1500*1500*1500 | 1900*1850*2200 | 40KW | |||

| HJ-07 | 800*600*1000 | 1400*1050*2100 | Single door | 20KW | Ambient temperature ~ 500℃ | |

| HJ-08 | 1400*1600*1400 | 2000*2050*2500 | Double door | 50KW | ||

| HJ-09 | 1800*1000*1500 | 2400*1500*2600 | 60KW | |||

| HJ-10 | 2000*2000*2000 | 2600*2500*3000 | 100KW | |||

| The workshop can be equipped with sample shelves or mobile carts. | ||||||

| The above are only some of the specifications. The appearance, size, temperature range, etc. can be customized according to customer requirements. | ||||||